Discover the Lasting Effectiveness of Bronze Bushing for Industrial Applications

Wiki Article

Selecting the Right Bearing Bushing for Ideal Performance

In the globe of equipment and commercial applications, the relevance of picking the appropriate bearing bushing can not be overemphasized. In this conversation, we will certainly discover the various types of bearing bushings, essential elements to think about, and important suggestions for installation and upkeep, all leading to the best objective of accomplishing optimal efficiency.Sorts Of Birthing Bushings

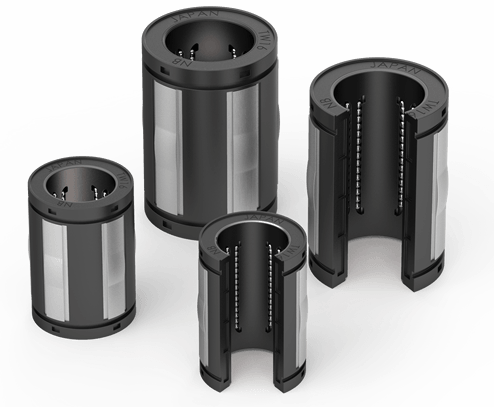

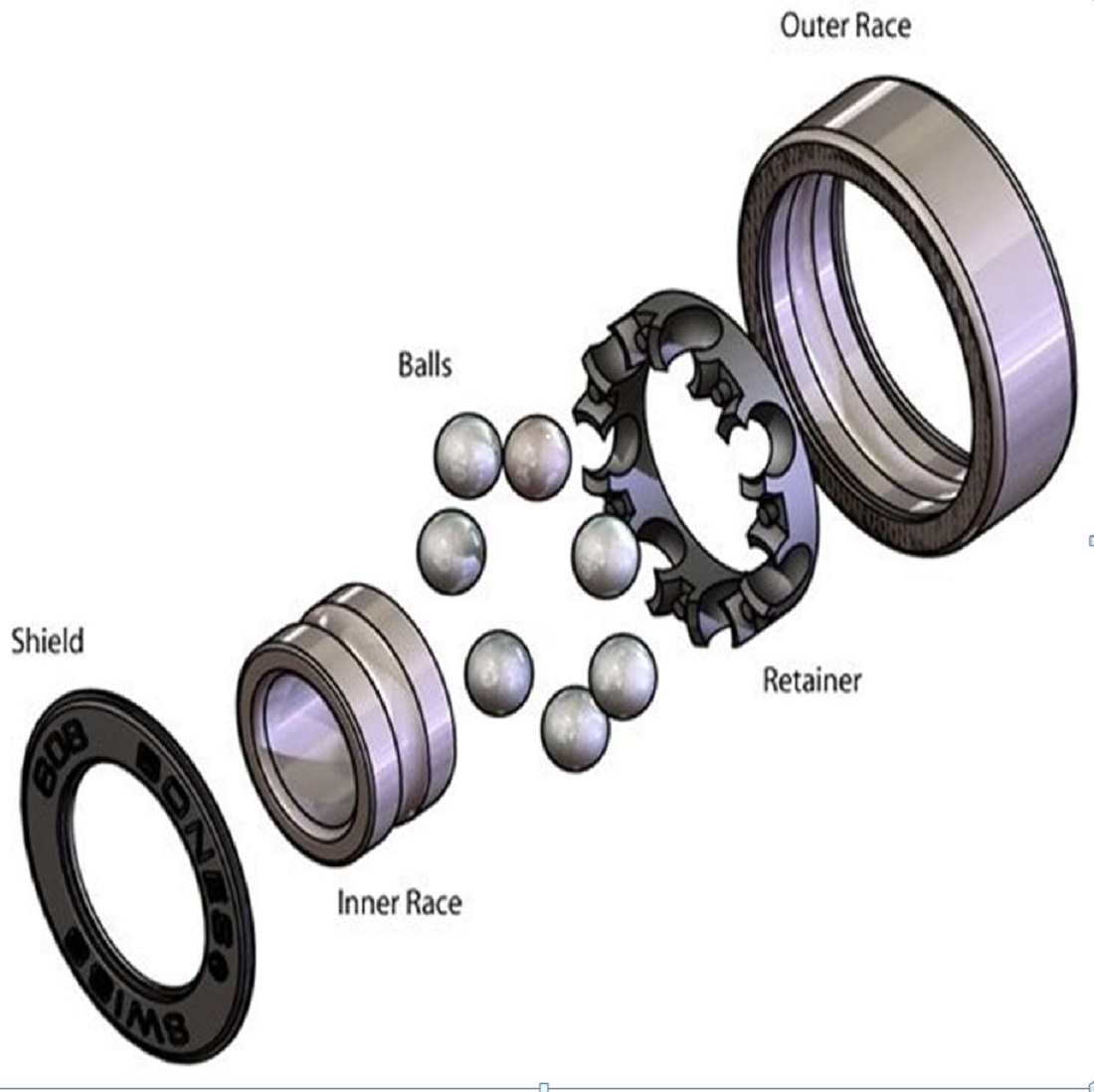

There are numerous different sorts of birthing bushings readily available for different applications. These bushings supply support and decrease rubbing in between moving parts in equipment and tools. One typical kind of bearing bushing is the simple bearing bushing. This sort of bushing consists of a cylindrical sleeve constructed from a low-friction material, such as bronze or plastic. Simple bearing bushings are ideal for low-load and low-speed applications, as they use excellent resistance to use and can deal with light to modest radial and axial tons.One more kind of birthing bushing is the flanged bushing. Flanged bushings have a flange or collar on one end, which helps to effectively position and line up the bushing within the housing.

Aspects for Consideration

When picking the ideal bearing bushing, there are several vital aspects to consider. These variables can dramatically affect the efficiency and longevity of the bushing, along with the overall performance of the machinery in which it is set up.One crucial factor to think about is the operating conditions in which the bearing bushing will certainly be used. This includes variables such as temperature, moisture, and the presence of destructive materials. Different products have differing resistance to these conditions, so it is important to choose a bushing that can stand up to the specific atmosphere it will certainly be revealed to.

Another aspect to take into consideration is the load and speed needs of the application. The bearing bushing need to be able to handle the awaited load and operate smoothly at the called for speed. Failure to select a bushing that fulfills these specifications can result in early wear and failing of the bushing.

Furthermore, the compatibility of the bearing bushing with the mating surface area need to be assessed. The bushing material need to be suitable with the shaft or real estate material to reduce friction and wear. It is also crucial to think about the lubrication needs of the bushing and make sure that the proper lubricant is made use of.

Lastly, the cost and schedule of the bearing bushing should be taken into consideration (bronze bushing). While it is important to select a bushing that satisfies the called for requirements, it is also vital to consider the budget plan and the availability of the picked bushing

Significance of Appropriate Lubrication

Correct lubrication is important for the optimum efficiency and longevity of a bearing bushing. A bearing bushing is an essential element in various applications, ranging from vehicle engines to commercial machinery. It assists lower rubbing and wear in between moving components, ensuring smooth operation and preventing early failing.Lubrication plays a crucial duty in keeping the health and wellness of a bearing bushing by decreasing rubbing and warm generation. By creating a slim movie of lubricating substance between the bearing surface areas, it lessens get in touch with and permits smooth activity. bronze bushing. This aids to stop extreme wear and tear, guaranteeing that the bearing bushing can withstand the high lots and rates it might experience

Additionally, correct lubrication also helps to dissipate warm produced throughout operation. Extreme heat can create the lubricating substance to break down, causing minimized lubricating properties and prospective damages to the bearing bushing. By selecting the ideal lube and making sure correct lubrication intervals, the temperature can be maintained within appropriate limitations, improving the general performance and longevity of the bearing bushing.

It is necessary to think about various factors when selecting the ideal lubricating substance for a bearing bushing, such as operating conditions, temperature level, company website rate, and lots (bronze bushing). In addition, normal upkeep and monitoring of lubricant levels are essential to guarantee that the bearing bushing is appropriately lubricated throughout its life span

Installment and Upkeep Tips

To make sure optimal performance and longevity of a bearing bushing, correct setup and upkeep are crucial. Incorrect installation can lead to imbalance and premature wear, lowering the general efficiency and life expectancy of the bushing.

In addition, routine straight from the source cleansing is required to remove any kind of dust, debris, or contaminants that might have collected on the surface area of the bushing. This can be done using a soft cloth or brush, taking treatment not to harm the bushing or scratch.

Selecting the Right Distributor

Selecting the best provider for your bearing bushing is a critical choice that can considerably influence the efficiency and dependability of your equipment. A trusted vendor will not just offer you with top quality bearing bushings yet likewise offer exceptional customer assistance and technical experience. When choosing a supplier, there are a number of factors to think about.Firstly, try to find a provider that concentrates on birthing bushings and has a tested record in the market. They need to have a broad array of products to satisfy your details needs and be experienced about the different kinds of bushings readily available.

Secondly, consider the vendor's reputation and client testimonials. Look for reviews from various other consumers to gauge their fulfillment with the distributor's services and products. A reliable distributor will certainly have favorable feedback and a strong credibility out there.

Finally, examine the distributor's production capabilities and quality assurance processes. Guarantee that they stick to stringent high quality requirements and have durable screening procedures in position to guarantee the dependability and toughness of their items.

Lastly, consider the vendor's Bonuses prices and delivery terms. While price is a crucial variable, it should not be the single determining aspect.

Verdict

In final thought, picking the appropriate bearing bushing is critical for accomplishing ideal efficiency. In general, making informed choices in these locations will add to the total success and performance of the bearing bushing.One typical kind of bearing bushing is the simple bearing bushing.An additional type of birthing bushing is the flanged bushing. Flanged bushings have a flange or collar on one end, which assists to appropriately align the bushing and place within the housing. Failure to pick a bushing that satisfies these specs can result in premature wear and failing of the bushing.

Choosing the appropriate distributor for your bearing bushing is an essential choice that can substantially impact the performance and reliability of your tools.

Report this wiki page